Jul 2, 2024

Reviews have been very positive for an entry level Graphic Installation Technician upskilling training course Work Based Learning Consortium (WBLC) developed for the sign industry in 2023, working with the Sign Association of Canada and individual sign companies across the country.

The Graphic Installation Technician Upskilling program was given to trainees in nine locations across Canada, from British Columbia to Nova Scotia – ranging from smaller, remote communities to urban settings. The multiple location approach was deliberately done to gauge both the effectiveness of the training and as well as the ability to deliver graphic training across the country in both large and small communities.

Delivered to Smaller Communities Across Canada

WBLC’s hybrid e-learning program enables technicians in smaller communities to train without having to worry about incurring high travel costs and more days away from their busy shop to access training, which can be common in smaller communities. WBLC’s hybrid learning programs typically include interactive e-learning, e-instructions, train the technical trainer, shop floor hands-on assignments, technical language training, on-the-job training, monitor coaching and certification.

Dramatic change after graphics applied to wall

“I thought it was good and definitely learned things,” says Brandon Pullin, a sign installer for TDH Experimental Fabrications in Surrey, B.C. “It gave a lot of valuable information and was very useful.”

Pullin explains that they do a lot of work with vinyl in creating signs and he greatly benefited from this upskilling program.

“Some of the information that I found very useful dealt with different types of vinyls, such as what vinyls can go together and what vinyls can’t go together, as well as details about the temperatures for applications. Some of that content I never knew before,” says Pullin.

Pullin notes that he tried unsuccessfully doing some work with vinyl in January. After he took the WBLC upskilling program, he realized that “it was a waste our time trying to apply vinyl in those times of years” because of the temperatures.

Kenny St. Croix, an 18-year sign industry veteran with Trim-Line United Sign in Dartmouth, Nova Scotia, also was interested in the newly created WBLC Graphic Installation Technician training.

| “Really good (upskilling program for) someone getting into the business or a good introduction to the graphic installation world” – Kenny St. Croix, Trim-Line United Sign, Dartmouth, Nova Scotia |

“I received a text message from my General Manager asking if I was interested and I thought you can never have too much knowledge,” explains St. Croix. “It was a good course and I felt it would be really good for someone getting into the business or a good introduction to the graphic installation world.”

He was interested in some programs and tools that were mentioned in the training that he hadn’t heard about before.

“There was mention of a couple of software applications and tools that I hadn’t seen — items that we didn’t use, so I was able to learn things about those applications,” says St. Croix. He also found it a useful refresher and thought the pace of the program was good.

“I think (the training pace) moved well and the quick tests were all pretty cool,” he adds.

Receives High Marks

In a general survey, the Graphic Installation Technician training received high marks from participants for conveying the fundamental skills to feel comfortable and confident in working in graphic installation. The presentation, exercises, quizzes and use of pictures, videos and animations were ranked as very useful or essential in the training.

“We’re very pleased with the feedback regarding the Graphic Installation Technician training,” adds Wayne Lamon, Director, Programs, WBLC. “Many noted that it teaches key fundamentals and, for some of the trainees, training via e-Learning was something new.

“This is a powerful new tool that the sign industry can use to train entry level staff. It utilizes techniques, content and e-Learning that is new to some in this industry, that has proven to be highly effective in other industries we’ve served,” adds Lamon. “Its exciting to offer new ways of training to an established industry that is seeking to add new people to the profession.”

Jun 11, 2024

In the U.S., wind turbine service technicians are one of the fastest growing jobs, according to the U.S. Bureau of Labor Statistics [1] and employment is projected to grow 45% from 2022 to 2032 [2] . Opportunities also exist in Canada, where the Canadian Wind Turbine industry has been growing and the industry is on the lookout for new talent. Canada is ranked 8th in the world for installed wind capacity (2022), already has 337 wind energy projects producing power [3] and added 1.7GW of new wind energy in 2023.

Industry growth is prompting government, training and education related firms to continue to build Canada’s talent base. It’s an employment category that many job-seekers might not have known about.

Combining Training & Education Talents to Build Tomorrow’s Talent

Work Based Learning Consortium (WBLC), which offers work-based learning and hiring programs, and Relay Education, which delivers renewable energy and environmental education programs, have joined forces to train and attract workers to this industry.

In early 2024, 60 Relay Education trainees (40 in Calgary and another 20 in Toronto) completed a combined program of WBLC’s Wind Turbine Blade Repair e-Learning and Relay Education’s safety training.

“The goal of this program with Relay Education is to take people from no knowledge to enough knowledge to make a decision about a job in the industry and also give them a leg up on getting employed,” says Paul Coleman, eLearning Instructor and Content Developer, part of the WBLC Virtual Learning Team. “We’re giving the employer an opportunity to interview people that have been really well vetted. They’ve learned some key information that they wouldn’t otherwise have picked up if they walked in off the street.”

“The program provides a really good view into the industry and shows they can get into good repetition career in the wind turbine industry,” adds Coleman.

An Employer Tries the Training Himself

“It was a phenomenal program” – Maad Baobaid, President, Tomorrow’s Solutions Inc.

Maad Baobaid, President of Calgary-based Tomorrow’s Solutions Inc., a company that provides highly skilled technicians for the renewable energy sector, wanted to assess the WBLC/Relay Education program to understand the breadth of training being offered. Tomorrow’s Solutions does construction work in the renewable energy sector and sees increasing operations & maintenance (O&M) opportunities.

“I connected with WBLC and Relay Education at a conference last year,” says Baobaid, who was impressed with the combined Wind Turbine Blade Repair e-Learning and Relay Education’s safety training. “I have a lot of renewable experience but wanted to expand my blade repair knowledge and also wanted to see the reaction of people going through the training program.”

“It was a phenomenal program,” says Baobaid of the combined training. “It went into details and incorporated a lot of great material. One of the key things is the safety aspect. Safety has to be implemented inside everybody’s head from the very start, especially with newer people into the industry.”

A Different Kind of Repair Technician

Baobaid says that people often don’t appreciate the scale of the wind turbines.

“Obviously, some people don’t really know what a blade looks like. It takes you off guard,” adds Baobaid. “It’s one thing repairing blades on the ground and it is, obviously, a completely different ball game in the air. Sometimes, you have to be hanging off the blades to do the major repairs on the turbines.”

Comprehensive and Eye-opening Learning

Tisa Wright Marshall who also recently completed the Wind Turbine Blade Repair program found the combined WBLC/Relay Education program very helpful.

“It was very eye opening. It was very interesting learning about fiberglass, balsa wood, adhesives, and PPE (personal protective equipment),” says Marshall. “I also liked learning the project aspect, seeing everything from the beginning — defining what a project is, learning when a technician would be dispatched, and so on. I come from an administration background, so those kinds of things were exciting.”

Marshall was surprised at the amount of detail and level of information that was learned in the program – “It was a little surprising, in a good way.”

“It was a great experience. The combined training was beautifully meshed together – both the e-Learning training and learning the high rescue training aspects,” adds Marshall.

Combining Forces to Deliver Required Training

Based on the feedback related to the wind turbine blade repair program, virtually all program participants have indirectly commented on the combined strength of the two organizations — a winning combination.

“It’s been exciting to have such positive feedback to this newly developed pilot program, while also giving people considering employment in the Wind Turbine Repair space some important skills and knowledge that will make them even more competitive as they seek jobs in this rapidly growing industry,” says Rick Stomphorst, Employer Relations Manager at WBLC.

Dec 14, 2023

Wind Turbines dot the landscape across Canada, standing 85 metres (280 feet) tall. That means a lot of the repair and maintenance involves people working high in the air to service these clean energy sources. Training is an important element and Work-Based Learning Consortium (WBLC) has created an introductory Wind Turbine Blade Repair program to assist in training new or recent hires. Funding for WBLC was provided by the Future Skills Centre.

Unknown to Most – Blades Require Repairs

“It’s a pretty severe environment for wind turbines,” says Aaron Miller, President of Composites Canada, which provides composite material to companies in many industries across Canada. “These blades don’t look like they’re doing much, lazily trundling away but, just given their sheer size, the tip speed can reach 100+ mph (160+ km/h), sometimes double that. So, you get a lot of erosion (caused by) anything that happens to be in the air (striking the spinning blades). You also get ice damage falling from an adjacent blade, among other things.”

| “In many industries, you can bring the product inside for a repair. This is extremely impractical with wind turbine blades – Aaron Miller, President of Composites Canada |

Frank Sabatier, Wind Technical Manager at Mistras Group Inc., agrees with the importance of doing a lot of work out in the field.

“Many companies don’t want to take the blades down unless they absolutely have to because it takes a five-figure sum to take them down and put them back up, involving cranes and other things,” says Sabatier, who works with technicians both in the U.S. and Canada. “Add in the logistical challenges with road access, platforms, and much more to overcome.”

Skilled Workers Required to Repair Blades

Training new workers and keeping technicians up to speed is an ongoing challenge and comes in several forms.

Sabatier says there are some courses offered by technical colleges, but a large portion of the training is done directly by companies using their own training curriculum. Training is also offered by original equipment manufacturers (OEMS) who build the wind turbines.

“Most big OEMs are located in the U.S., so if a technician were to start working for Siemens or GE, they would receive their training in the U.S., because Canada just doesn’t have the facilities,” says Sabatier.

Training in composite materials is an area that Miller believes could use some assistance.

“There’s not a lot of training content or training material for the composite industry. Composites pop up in all kinds of strange and unexpected ways,” says Composites Canada’s Miller. “Wind turbines are fairly obvious because there aren’t very many other suitable materials to make these blades.”

WBLC Introduces an Upskilling Option

WBLC launched a pilot entry level Wind Turbine Blade Repair training program in 2023 that focuses on working with composite materials. The training was offered in conjunction with Relay Education, which delivers renewable energy and environmental education and training programs in classrooms and communities.

The WBLC program is designed to initiate people into the wind turbine industry. It covers applications and equipment used in wind turbine blades, mathematics, and understanding work documents.

Composite Canada’s Miller worries that there are gaps in the knowledge of working with composites in the field, so he welcomed the opportunity to work with WBLC on constructing a new entry level training program.

“This is a great program for a level-one person to learn about the industry,” say Reema Duggal, a lead for the virtual learning initiatives with Work-Based Learning Consortium (WBLC), who designs much of the e-Learning. “The reality is that there is no training for wind blade repair, locally, or that we can find in Canada. Each of the companies does their own training. So, this is a way to entice people to come to the industry and find out what the job is all about.

“For people interested in the industry, if you’ve gone through this our training, you are a much more valued applicant,” adds Duggal.

Trainees Found the Upskilling Program Valuable

“This WBLC program was definitely very helpful with a few videos and also quizzes that were at the end of each unit and that definitely helped me gain more knowledge,” says Justin Lau, a York University environmental studies student, who took a Relay Education Wind Energy Operations course at Holland College in PEI and then completed the WBLC training.

| “I’ve had a great introduction to the industry for wind turbine blade repairs and I am definitely way more confident in doing it in real life” – Justin Lau, Relay Education Wind Energy Operations student |

“I have not worked with fibreglass or carbon fibre or any type of composites before, but I think with this eLearning course, I’ve had a great introduction to the industry for wind turbine blade repairs and I am definitely way more confident in doing it in real life. I’ve learned a lot of the basics, especially with the composition of wind turbine blades and also a lot on the fibreglass repairing units.”

Lau says he’s likely to pursue a career in the wind industry, starting out as a wind turbine blade repair technician.

Another student, Ahmad Jabar has a background in electronics and is very interested in Green Energy. He also took Relay Education’s Wind Energy Operations course and then also followed up with the WBLC program.

“It was very helpful indeed! I really enjoyed every part of it and got to learn about many concepts that I had no idea about before enrolling in the program,” says Jabar. “Knowing about the whole process for Blades manufacturing was insightful and informative. It was interesting to learn about the difference in fiberglass and carbon fiber.

“It was surprising and intriguing to know about the procedure on how to fix blades defects while hanging in the air,” adds Jabar. “I think e-Learning is very convenient and it helps specifically when having busy schedules. To study at my own pace helped do more with my time.”

Work is planned to expand the new Wind Turbine Blade Repair program and develop other programs required by the Wind Turbine industry.

Oct 26, 2023

Upskilling or reskilling is happening daily across the country as organizations seek to narrow the skills gap. But surprisingly, it appears that many businesses do little in terms of tracking such an important component of their training strategy, resulting in an inability to make evidence-based decisions around workforce training.

Leveraging some data collection capabilities, employers could potentially make better utilization of their staffing requirements and their training needs. They could ask themselves:

- How many employees working in their current job would realize a performance improvement with additional training?

- How many employees could be moved to a more complex job with additional training?

- How many employees could move into a different job with comparable complexity with additional training?

By answering these questions, could employers potentially make more informed decisions about their staffing and training mix? Would government policy makers be better informed if they had more relevant data on actual upskilling and reskilling requirements? We think so.

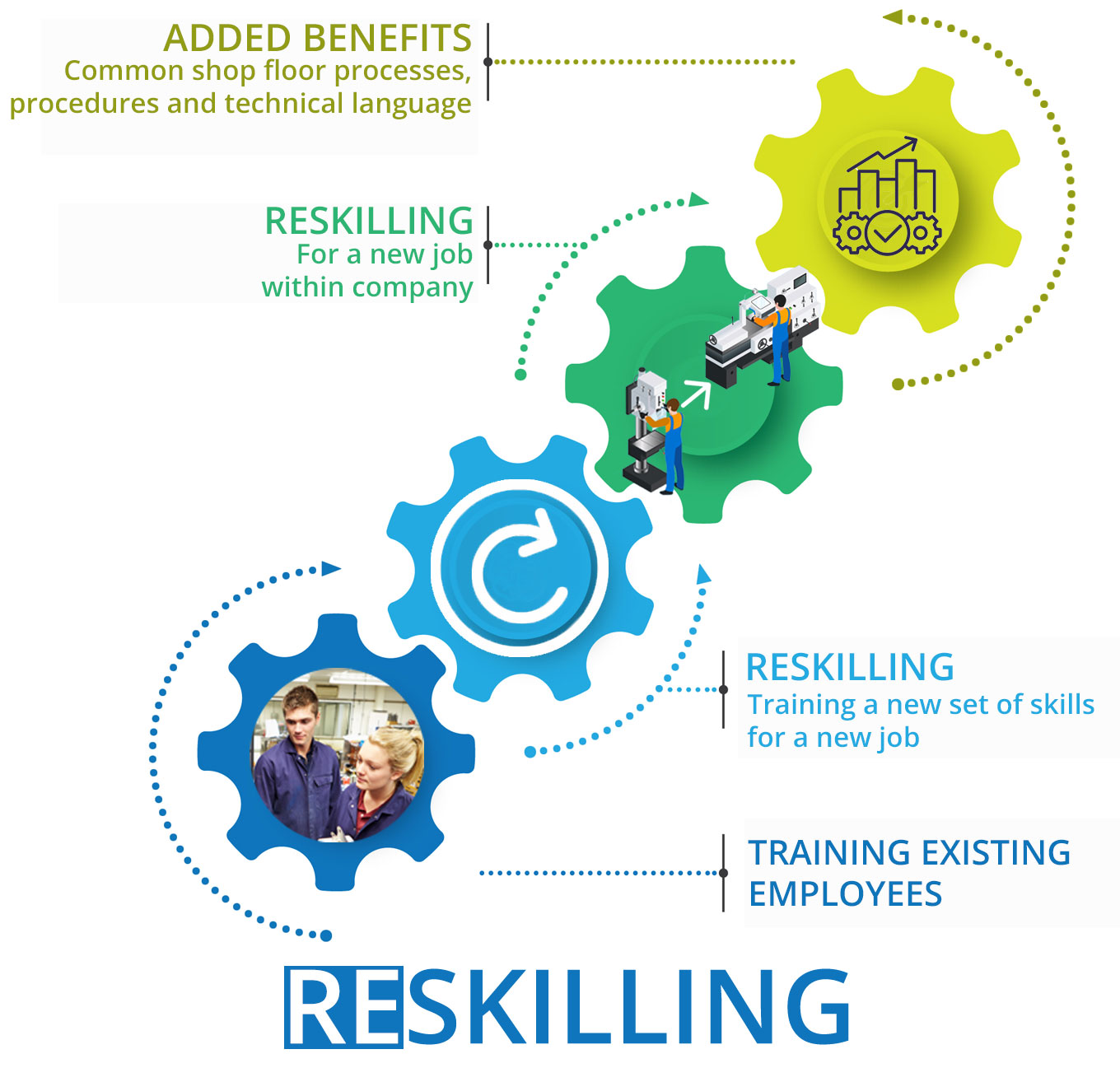

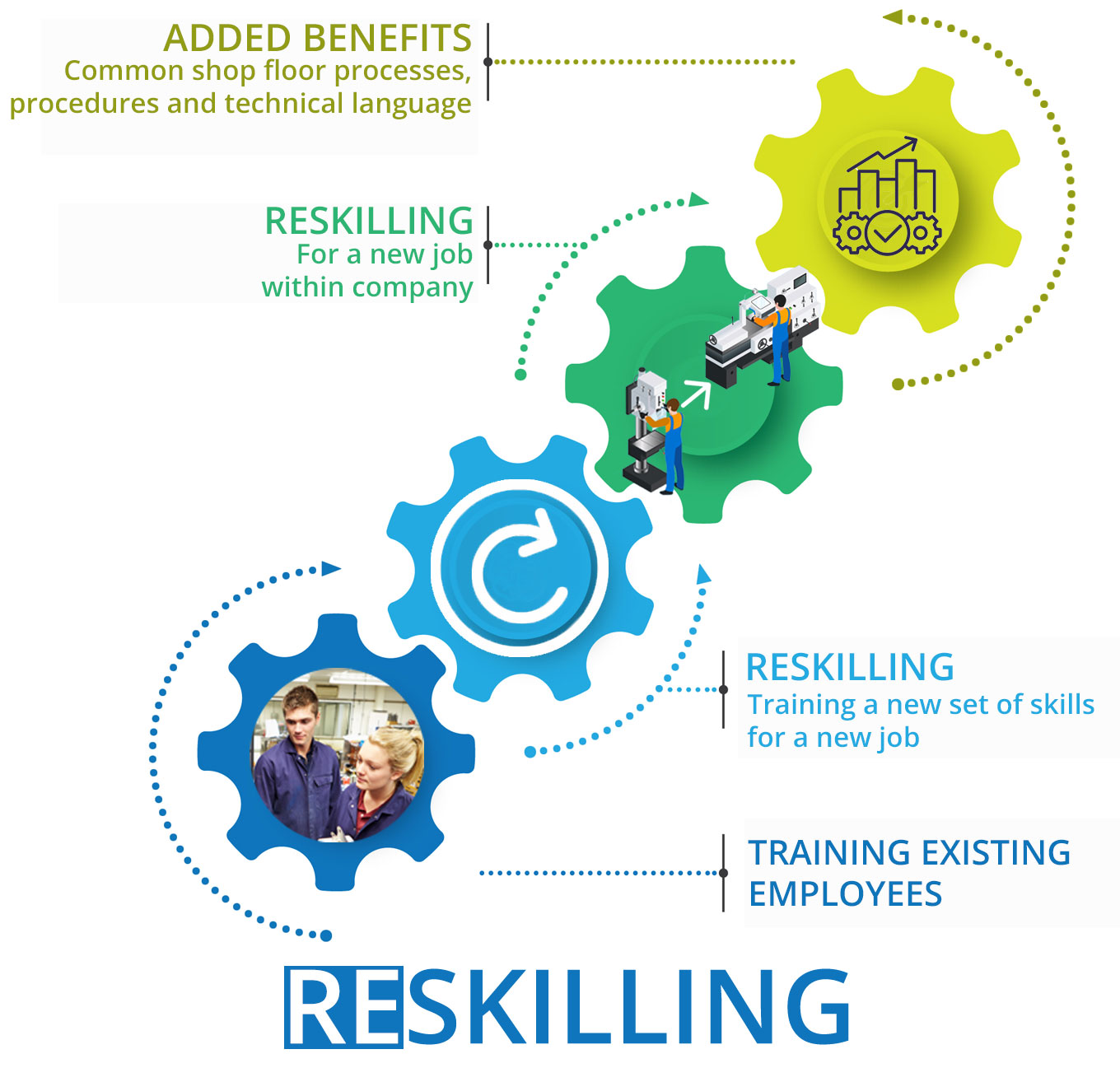

What is Upskilling and Reskilling?

It’s useful to have a baseline understanding of the two terms ‘upskilling’ and ‘reskilling’.

Upskilling: Training existing employees to meet the changing skill requirements for their existing job.

Reskilling: Training existing employees with a new set of skills for a new job within the company.

Upskilling is often the terminology used when hiring new employees who lack direct work experience in their new job.

“These definitions are typically used to define training for existing employees, but they also can be used for new employees,” says Morley Gunderson, a Canadian labour economist and Professor Emeritus at the Centre for Industrial Relations and Human Resources, University of Toronto. “There are no hard and fast definitions in the literature out there.”

Work Based Learning Consortium (WBLC) discovered some companies have a broader view of upskilling.

Work Based Learning Consortium (WBLC) discovered some companies have a broader view of upskilling.

“Many of the employers we work with had a broader definition of upskilling,” says Wayne Lamon, Director, Programs, WBLC. “They consider upskilling to include training existing employees already in a specific position, as well as the new hires.”

Lamon explains that several employers, who had hired a large number of new employees at one time, wanted to ensure these new employees all achieved a specific level of competency. But they also wanted existing staff (not just the newly hired employees) in a specific job, such as CNC machinists, to receive that same training.

“This ensures that everyone learns and uses the same processes and terminology on the job, whether they are a new hire or an existing employee,” adds Lamon. “It’s tremendously beneficial and many of these employers noted that our upskilling training led to a strong uptick in efficiency and productivity across the board.”

The Information Gap Around Upskilling/Reskilling

While it is assumed that there is a lot of upskilling and reskilling occurring, WBLC discovered that few companies track it with any thoroughness.“

If you’re a policy maker or a corporate executive and trying to sort through the challenges of the skills gap, you’ll likely be surprised to learn that there is no valid data source available for upskilling,” says Lamon. Further he goes on to say – “How much upskilling is being undertaken by employers? What assistance is required around upskilling? How much upskilling work is being undertaken by employers on their own?”

There’s an information gap that currently exists. Lamon believes WBLC has a solution to address this knowledge gap.

Creating an Upskilling Database for Industry and Government

As a result, WBLC has engaged with Future Skills Centre (a Government of Canada initiative dedicated to helping Canadians gain the skills needed to thrive in today’s changing labour market) to build a conceptual upskilling data collection system and work with some Canadian companies on a trial application of that system.

The first step was to conduct research around upskilling. This involved looking at the definitions of upskilling and reskilling. It also involved looking at what type of information is available to help companies and policy makers with decision making regarding upskilling and reskilling. WBLC also researched trends around upskilling and reskilling.There was a surprising amount of information about upskills/reskilling, but very little in the form of data.

| “If I’m an employer with an internal skills challenge and I’m facing the great resignation after the pandemic, I need to know what’s happening in the general market. For those in the industry, finding the right information is likely to prove challenging,” – Canadian labour economist and Professor Emeritus at the Centre for Industrial Relations and Human Resources, University of Toronto |

“If I’m an employer with an internal skills challenge and I’m facing the great resignation after the pandemic, I need to know what’s happening in the general market. For those in the industry, finding the right information is likely to prove challenging,” says Gunderson, who conducted the research elements of this project. “The real problem is ‘sorting the wheat from the chaff’, or as we say more formally in the statistical analysis, ‘finding the signal given the noise’ that’s out there.”

The second step was to build a data collection system, which WBLC recently completed.

WBLC also has identified an industry group to pilot and test the system, which will include working with Linamar of Guelph and the Canadian Association of Mold Makers (CAMM) member companies.

“We’re just about to launch this aspect of the project and it will be fascinating to see the results,” says Lamon. “We believe employers and policy makers within government could really benefit from this new type of information.”

Benefits of data tracking

Lastly, Lamon explains that tracking upskilling and reskilling data could potentially lead to better informed, evidence-based decisions.

For example, by evaluating the data, executives at a trade association could verify at a glance that while there are 2,000 vacancies for a particular position within the industry, there also are an additional 3,000 people already employed in that role who require upskilling.

“Equipped with this information, industry can potentially reach out to government to talk about how they could collaborate to address the issue and government policy makers will have a clearer understanding of the whole picture because data would now exist to support decision making,” adds Lamon.

Sep 20, 2023

Ad-hoc, on-the-job training has been practiced for ages. The problem is there is no defined finish line, nor the associated recognition of achievement at the end.

There are considerable practical and important benefits for industry, workers and others in certification programs for various job training programs:

- It builds awareness of the quality of your trainees

- For company managers, it provides an objective measurement for you that your employees are competent in the technical elements of their job

- Certification helps employees validate their career choice, see the value of learning and generates excitement about gaining new credentials

- It often increases interest from potential applicants to a sector that employs certification, compared to other sectors that do not offer certification

- Over time, companies see both an increase in the capabilities of their employees and also an increase in their retention rates

How Does the Certification Process Work?

Prior to developing any training, WBLC works with industry subject manager experts to define the technical learning outcomes that are required to successfully complete a training program for a specific job. WBLC then creates a learning program that ensures all the required key knowledge elements have been embedded into the training program.

At the end of the training, the WBLC assesses and, if fully satisfactory, independently certifies Trainees’ qualifications and skill levels for the job at the completion of their ‘On-the-Job’ learning and awards the trainee a WBLC Certificate.

For example, the certification process for a CNC Machinist involves the trainee successfully passing tests administered during the e-Learning and practical ‘on-the-job’ training. During the process, the trainee demonstrates their knowledge of general manufacturing technical practices and procedures, and knowledge of technical work practices by completing an on-line examination.

In the CNC Machinist program, an independent WBLC Assessor verifies that the Trainee can set up machines and produce parts as per work orders or approved drawings while meeting all required quality standards and scrap standards. This outcome will be assessed at the conclusion of the training by having the WBLC Assessor observe the Trainee performing required job tasks and completing a practical assessment.

WBLC has established an industry recognized finish line and those that successfully cross it, receive a certificate.

Jul 24, 2023

Benefits of Training your Technical Trainer First

- Newly hired employees become more proficient faster

- Reduce rework and generate less scrap

- Training existing employees on new equipment/processes

|

- Experienced skilled workers spend less time training

- Safer workers with fewer accidents

|

On-the-job training happens across the country every day but how that training is delivered can greatly impact the effectiveness of the training. Companies often ask their most knowledgeable, experienced workers to be trainers since they possess the expertise which the trainee needs to learn to do the job. In the manufacturing, maintenance and technical service industries, these trainers are often called Technical Trainers.

But just because they have the experience, it doesn’t mean that these trainers have learned how to pass along that knowledge to others.

| “if (the employer’s technical trainers) are trained in effective job instruction, they will make a significant positive difference in how quickly and effectively the trainee is learning” – Pavel Wegrzyn, a mentor/coach with Work Based Learning Consortium |

“We’ve seen in our programs with clients that their technical trainer, if they are trained in effective job instruction, they will make a significant positive difference in how quickly and effectively the trainee is learning,” says Pavel Wegrzyn, a mentor/coach with Work-Based Learning Consortium (WBLC).

A key aspect of WBLC’s hybrid approach to training and e-learning includes a train-the-trainer element called the Technical Training Effectiveness Workshop (TTEW), which provides rapid and effective training for the trainers onsite. It equips the employers’ most experienced skilled workers to be more effective in their training efforts.

“When we started thinking of creating the Technical Training Effectiveness Workshop, we asked companies if they felt a train-the-trainer program is needed or would be helpful,” says Rod Jones, Managing Director of WBLC. “Companies said there was nothing they could find that would help their trainers. Or, when there was a program, they’d have to send their trainers off-site for several weeks or send them to a long program where training trainers was only one element.”

There clearly was a need for a rapid, focused program on job instruction training and WBLC set out to address it.

Maximizing Adult Learning Effectiveness

WBLC recognizes how busy trainers are with their work. Leadership coach, facilitator and organizational development consultant Bob Nager worked with WBLC to develop the workshop which consists of two 90-minute virtual sessions. After completing the workshops, trainers are supported by weekly meetings with WBLC mentor coaches.

“Our approach has been to get employers to identify experts on the job, who have been doing their job for years, and then provide them with directly relevant knowledge and a proven time-tested process to be able to effectively do technical training,” says Bob Nager, who also has a Master’s degree in Adult Education, Workplace Learning and Change from the University of Toronto.

“Adults learn much better when they are self-directed and self-motivated,” says Nager. “People will retain knowledge much better when they understand ‘why’. If you just go by rote and teach people material, maybe they’ll learn it, but it won’t work as well as allowing them to understand the reasons why they’re doing things.”

The workshop also includes an experiential learning element where trainees watch a trainer perform a task they are about to learn. The trainees are asked to replicate the task and explain why they are doing what they’re doing – integrating it into their thinking. The examples used in the workshop are crafted by the WBLC Learning team and then put on video to demonstrate the trainer instructing a trainee in tasks that are relevant to the job sector using the program.

A Proven Methodology – from WWII to Modern Lean Manufacturing

Nager explains that the WBLC Technical Training Effectiveness Workshop is based on a methodology called Training Within Industry (TWI) that originated during the Second World War by the U.S. government. TWI has since been adopted by the Lean manufacturing sector.

“Not unlike the challenges facing manufacturers today, the war effort required bringing thousands of people into factories in a very short time, where many had no previous manufacturing experience,” explains Nager. “They recognized they needed to rapidly upskill workers quickly to deliver quality outcomes.”

“The TWI methodology is a tried and tested methodology adopted by the Lean manufacturing sector. We have lots of evidence that it really delivers great outcomes,” adds Nagar.

The training workshop provides technical trainers with an easy-to-use framework for performing their training work. Previous attendees have repeatedly shared with us that the WBLC framework gives them confidence in working with their trainees. The technical trainers also are taught to recognize that people learn differently and learn tips on how to factor that into their instructional approach.

After the workshop, the technical trainers have weekly calls with coach monitors to help them with challenges they’re encountering, discuss progress made, answer any questions related to the training methodology, as well as provide tips. These weekly calls are additional support for the trainers and also are used to evaluate the effectiveness of both the TTEW workshop and the trainers themselves.

Valuing the Training

The train-the-trainer workshop has advantages for both the company and the trainers. Sometimes, experienced workers are asked to train others in addition to their regular day-to-day duties. This can be a challenge.

“The Technical Training Effectiveness Workshop demonstrates that the company acknowledges that technical training is as part the trainer’s individual’s job,” adds Nagar. “Now there’s the acknowledgement from the employer. Trainers are pleased to have their training skill recognized, and really start to take pride in bringing their trainees along. It immediately increases their confidence.”

The effect is improved training results, a faster training process, reduced re-training time, less rework and scrap, and safer workers with fewer accidents. The result is faster payback for employers.

| “Knowledge obtained from WBLC’s Technical Training Effectiveness Workshop is an enduring asset…it continually pays dividends ” – Rod Jones, Managing Director of the Work Based Learning Consortium |

“The good news is the knowledge obtained from the WBLC workshop is an enduring asset because once people know how to do it, as long as they apply it, it continually pays dividends” says Jones.

Trainers are set up for success and there are clear business results – newly hired employees become proficient more quickly and experienced skilled workers spend less time training.

“Companies need qualified people as there are significant skills shortages in some sectors and firms need people to be up to speed and trained quickly,” adds Nagar.

The Technical Training Effectiveness Workshop can be a key element of the training and upskilling solution for your company.

Work Based Learning Consortium (WBLC) discovered some companies have a broader view of upskilling.

Work Based Learning Consortium (WBLC) discovered some companies have a broader view of upskilling.