CNC Machine Operator Hiring & Upskilling Program

Skills shortages? Team up with WBLC to upskill your current employees in 2 months.

Quick | Reliable | High ROI

Do you need capable CNC Machine Operators to increase capacity or replace retirees? Can’t find experienced people to hire or can’t wait for on-the-job training to happen? Here’s a solution that works: a proven training program to upskill your current workers.

Your current employees can be more proficient on the job:

- formalized, enhanced CNC technical knowledge and skills

- fully certified to the industry-defined technical job standard for

CNC Machine Operators

Your Trainers can be more effective and spend less time with Trainees:

- a proven 4-step process for teaching technical skills

- practical guidance on interpersonal skills with diverse trainees

Your company can get a fast ROI on your investment:

- Payback in less than 4 months.

You can be confident of success – WBLC’s Work-Based Learning Programs are proven in practice:

- over 60 advanced manufacturing companies in Ontario have partnered with WBLC

- over 600 employees quickly learned skilled jobs

- over 90% success rate

What’s Included In The Program

The WBLC CNC Machine Operator Program drives business results with elearning and on-the-job training that immediately improves your employee’s production performance.

E-learning includes a comprehensive curriculum based on industry defined technical learning outcomes. The modules include text, graphics, photos, animation, video, and quizzes that ensure the participant’s maximum attention and interest.

Tests, Shop Floor Assignments, Exams, and Experienced Observation measure the performance and success of participants.

Weekly Virtual Classroom sessions support self paced e-learning by engaging participants in meaningful discussions and help answer all questions.

Monthly Mentor Coach visits to your shop to support the participants in achieving proficiency.

A Shop Floor Effectiveness Workshop For Technical Trainers supports your Trainers to guide the participants.

CNC Machine Operator elearning Modules

Intro To CNC Manufacturing

- CNC Terminology

- General Shop Safety

- Machines Used In CNC Manucaturing

- CNC Machining Videos

- CNC Machined Parts – Common Features

- Shop Floor Assignment

- Intro To CNC Manufacturing Test

Core + CNC Mathematics

- Addition and Subtraction

- Multiplication and Division

- Fractions

- Statistics

- Measurement

- Ordinate Dimensions

- Shop Floor Assignment

- Core + CNC Mathematics Test

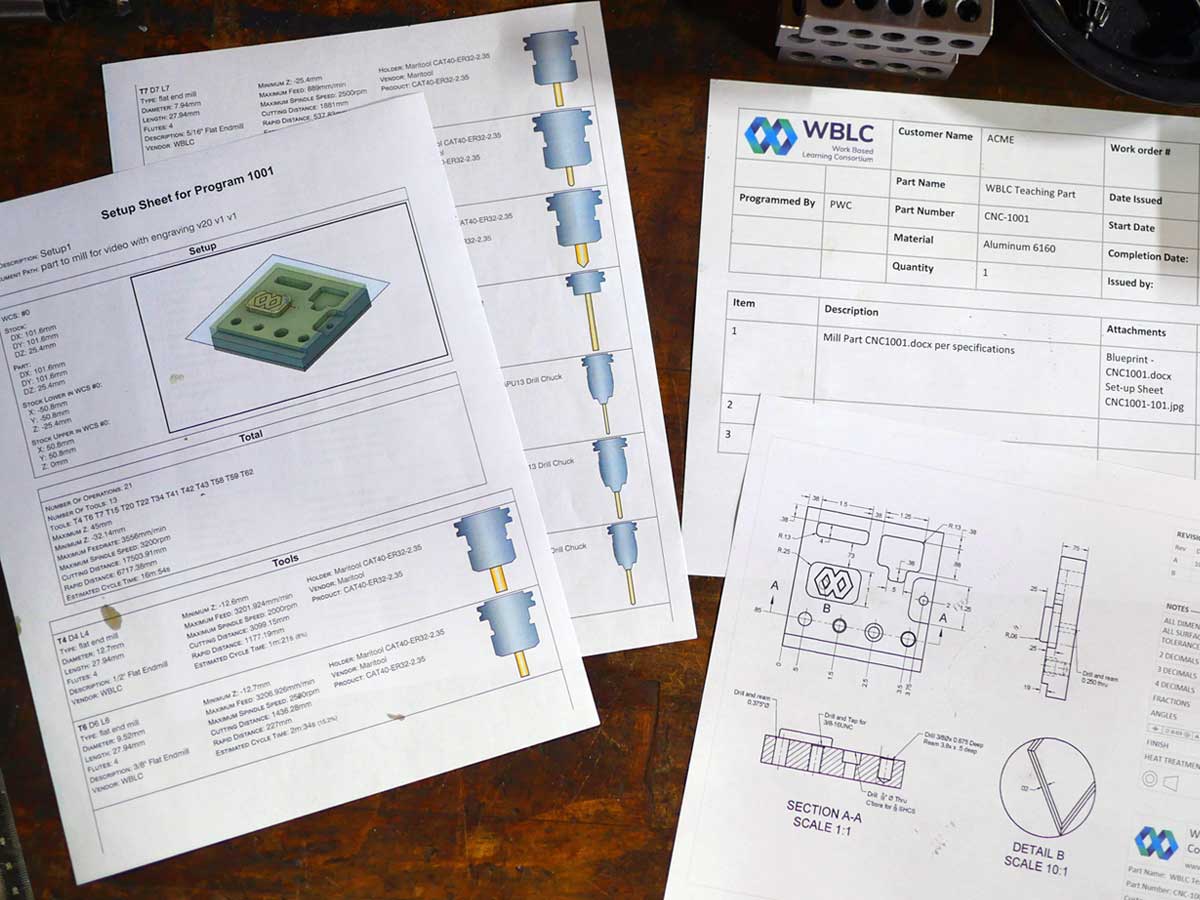

CNC Work Documents

- Standard Work Instructions

- Blueprint Basics

- Process Specification Sheets

- Operator Data Sheet

- Tool Path Drawings

- Used Tool Tag For Non Conforming Tool

- Nonconforming Material (Hold) Tag (aka MRB Tags)

- Pre-Use Inspection Sheets

Technical Language Learning – Part 1

Your CNC Toolbox

- Tools For Measuring

- Tools For Material Handling and Applying Force

- Tools For Grasping and Fastening

- Tools For Shaping and Deburring

- Tools For Cleaning

- Shop Floor Assignment

- CNC Toolbox Test

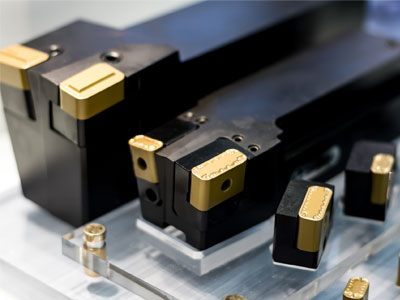

CNC Machining Tools & Fixtures

- How CNC Cutting Works

- CNC Cutting Tools

- CNC Holding Fixtures

- CNC Controller

- Shop Floor Assignment

- CNC Cutting Tools & Fixtures Test

Technical Language Learning – Part 2

Operating CNC Machines

- Preparation and Planning

- Producing Parts On A Mill

- Producing Parts On A Lathe

- Running Multiple Machines

- Post Production Steps

CNC Machine Operator Virtual Classroom and Shop Floor Training

Weekly Virtual Classroom Sessions

Our E-Learning Instructor works with participants every week over Zoom to discuss the content covered in the e-learning, answer questions, and support the participants in their learning journey.

The e-learning instructor also discusses the Shop Floor Assignments as they offer practical hands on direction to learn about all elements of CNC machines.

Monthly Mentor Coach Visits

Our Mentor Coaches monitor the progress of the participant and conduct assessments as part of the certification process.

They also support your Trainers by answering questions and providing guidance on the program.

Technical Trainers Workshop

The Technical Training Effectiveness Workshop improves your Technical Trainers effectiveness in managing employees via two 90 minute workshops.

Trainers find they are far more confident and get more out of employees after attending these workshops. Learn more >

WBLC Certification

WBLC certifies participants after they have successfully passed the tests and exams in e-learning, demonstrated understanding of topics to the e-learning Instructor, and demonstrated proficiency on the shop floor to your Trainer and the Mentor Coaches.

What Participants Are Saying About The Program

I had no experience at all with CNC machining.

I can say with confidence that this program truly changed my life and gave me the motivation to pursue an abandoned dream when I thought these opportunities didn’t even exist.

Sanjiv Uthayakumar, Toronto

I was surprised there was such a support network for (the training). I didn’t expect to be supported so well through this training program.

Trainee, Guelph

Our skilled workforce, like many other companies, are in the 40+ age range. We missed an entire generation of skilled people. I feel the program is working out very well. I talked with other companies, and they’re feeling the same way, it’s a really good program.

Robert Flack, President – Hibar Systems

Companies Already Benefiting From The Program

Let’s Get Started

Let us help you solve your skills shortage by training your employees to become CNC Machine Operators