CNC Programmer

Work-Based Learning Program:

Info for Job Seekers

CNC Programmer: Job Seeker Info

Hiring In The Future

CNC Programmers are vital to Ontario advanced manufacturing businesses. CNC Programmers develop software programs that direct CNC (computer numerically controlled) machines to cut and shape metal or plastic to produce components for airplanes, automobiles, tools/dies/moulds and other industrial machined parts and tools. Using 3-dimensional computer designs (CAD models) and/or blueprints that define the configuration of the required component, CNC Programmers use CAM (computer-aided manufacturing) software programs to generate the program code that guides CNC machines to perform machining operations which result in precise finished components – efficiently and safely.

BUT – many Ontario advanced manufacturing companies are reporting a shortage of capable, experienced CNC Programmers. And that’s where we come in. We are the WBLC – and we’ve brought together Ontario advanced manufacturing companies to solve this challenge. We’ve launched the CNC Programmer [Level 1] Selection and Learning Program – a program that helps Youth aged 18-29 get hired by a participating Ontario advanced manufacturing company, complete the WBLC CNC Programmer [Level 1] Learning Program (approx. 25 weeks of paid classroom/computer lab + on-the-job training) and become Certified as an WBLC CNC Programmer [Level 1], leading usually to continuing full-time employment with the participating Ontario advanced manufacturing company and to future career opportunities at that company and at other Ontario advanced manufacturing companies.

Is This the Opportunity You’ve Been Looking For?

- Do you have good math skills?

- Do you like working with CAD design programs?

- Do you have 3-dimensional thinking?

- Are you good with details?Do you enjoy working relatively independently?

- Do you like having responsibility and being accountable for your work?

- Do you have good communication skills?

If you can answer YES to most of these questions, then being a CNC Programmer could be a good job for you, and the start of a rewarding career in advanced manufacturing.

Do you like working with computers / software?

What Exactly Is CNC?

And What Does A CNC Programmer Do?

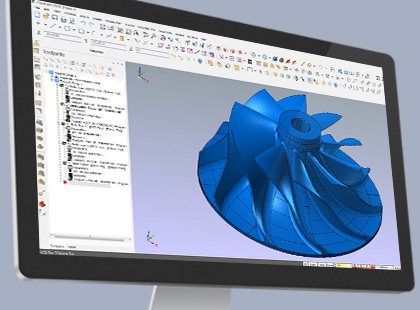

A CNC Programmer uses CAM software such as Mastercam to generate program code that controls the operations of a CNC machine. These CNC machines, such as mills, lathes, EDM, laser or waterjet cutters, follow the program code to perform a series of machining operations (rough cutting, finish cutting, shaping, pocketing, profiling, turning, drilling, tapping, threading, etc.) to produce the required components.

CNC Programmers analyze job orders, review CAD models and/or blueprints, make calculations to determine where materials should be cut, define the best sequence of machining steps, decide tools, speeds, feeds and fixtures to be used, then generate program code using computer-aided-manufacturing (CAM) software to capture all these decisions; run simulation tests; conduct quality testing and correct/improve program code to increase efficiency, quality and safety; and communicate with other programmers, shop floor management, machinists/setup and operators and engineering and sales staff to achieve this.

Essentially, CNC Programmers, using CAM software, build the program code that directs the operations of CNC machines so CNC Machinists and CNC Operators can set up and operate CNC machines to produce machined components that precisely match the required design – efficiently and safely.

What Will You Get Out Of This Job?

The job pays well. Starting wages are usually between $20.00 and $24.00 per hour. After two years of experience, CNC Programmers are paid approximately $28/hour on average, and fully experienced CNC Programmers may earn $35/hour or more. Depending on the firm they are working for, they may also be eligible to receive bonuses.

This can be a life-altering opportunity. Becoming a CNC Programmer can be an excellent decision for you. The job is interesting and pays well. It is in demand and is unlikely to be eliminated as manufacturing processes change and evolve. Long-term employment and the stability it brings is a good thing to have in a job

Check Out These Videos On CNC Machining

Millturn CNC Machine | EMCO Group

Cycle Start Show | Machining Process

Mazak Integrex Machine

CNC Parts, Machines, and Tools

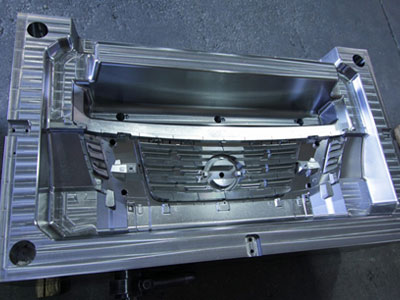

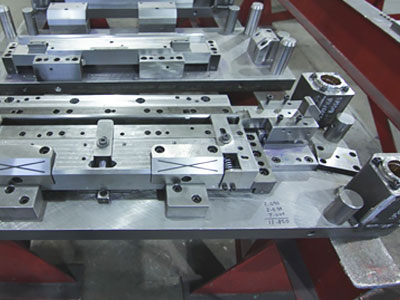

These are some of the parts, machines, & tools that are part of the CNC machining process & output.

Actuator Assembly

Aircraft Engine Mount

Aircraft Landing Gear Axle

Mold for Automotive Front Grill

Gear Cluster

Hurco 3 Axis

Mold Shoe

Punch and Die Shoes

How Does The Program Work?

The CNC Programmer Work-Based Learning Program is a great opportunity to learn in-demand skills and get a great stable job. The program works like this:

Apply to the WBLC CNC Programmer Work-Based Learning Program

To apply to WBLC and complete the WBLC Online Assessment, please click “Apply to WBLC” below or above.

The WBLC Online Assessment will help you to understand your current aptitudes, attitudes, and personal characteristics. For some people, their natural abilities and talents fit perfectly with the job. Hopefully that’s you!

When WBLC has reviewed your completed online assessment, Manpower will contact you if you have been selected to proceed to the WBLC Interview process.

Go Through the WBLC Interview Process

Manpower will contact you by phone to arrange for an in-person interview to confirm your eligibility for this program and to understand more about your aptitude, attitude, and personal characteristics.

This is an important interview.

They will also speak to you about your availability to travel outside your preferred location for opportunities.

If you pass the WBLC Online Assessment and this WBLC Interview, you are now a Candidate for hiring by an Ontario advanced manufacturing company who is participating in this WBLC Work-Based Learning program.

Get Hired by a Canadian Advanced Manufacturing Company

Participating companies who are interested in hiring you will invite you for an interview and a tour of the company. Manpower will coordinate your interviews.

An employment interview is a very important one, so you should prepare yourself well and make every effort to present yourself positively.

If the company extends an offer of employment and if you choose to accept – you will now become an employee of the hiring company and a Trainee in the WBLC CNC Programmer Work-Based Learning Program. That means you will receive a pay cheque from your company while you are learning your new job.

Acquire the Basic Theoretical Knowledge and Basic Practical Skills

(e-Learning + Classroom Learning)

Over approximately 7 months, you will acquire the basic theoretical knowledge and basic practical skills for your job through a combination of:

- E-Learning: delivered online at your employer in the earlier months

- Classroom training: limited to about 2-3 weeks at an outside location

- On the job training: throughout the entire 7 months

The basic theoretical knowledge and basic practical skills (competencies) you will acquire include all the following topics:

- Manufacturing Terminology

- Types of CNC Machines

- CNC Machine Operations

- Machine Maintenance Practices

- Blueprint Reading

- Applied Math

- Materials

- Tools

- Measurement

- Cutting Fluids

- Workplace Safety

- WHMIS

Get On-The Job Training to become a CNC Programmer

This part of the program is about 23 weeks. There are very clear industry-developed Technical Learning Outcomes (TLOs) defined for the entire training period.

During your on-the-job training, you will not be on your own to learn the job. There will be a trainer helping you – providing instruction, assistance and direction. Your trainer will review the Technical Learning Outcomes with you and be responsible for making sure you are progressing towards completing them by the end of the on-the-job training period.

Further details on this important phase are in the CNC Programmer Job Overview pdf (above)

Get Certified by WBLC

As you progress towards the completion of your WBLC program, you have the opportunity to be certified by WBLC as a CNC Programmer. Certification is a public statement that you have passed and are highly qualified to perform specified duties – in this case, those of a CNC Programmer.

WBLC’s certification process consists of testing and assessing your mastery of the Technical Learning Outcomes for the job and, if acceptable, certifying you as a CNC Programmer based on:

- your successful passing of tests administered during the e-learning and classroom training

- demonstrating to our WBLC Assessor that you can carry out mold maintenance operations as per work orders, drawings and process instructions

- Demonstrating your knowledge of general manufacturing technical practices and procedures and knowledge of CNC specific technical work practices by completing an on-line examination.

At this point, you will have clear, objective evidence that you are a WBLC Certified Mold Maintenance Technician [Level 1] who can be a productive, valuable, promotable employee and advance your career going forward with your employer by contributing to the greater business success of the company.

The certification will be issued by the Work-Based Learning Consortium and over time will be accepted by many employers as evidence of your capability and expertise.