QuickLearn

microlearning modules for CNC Machinists

Need the ability to quickly assess candidate skills, onboard new hires, or upskill employees on important CNC concepts?

We’ve built a microlearning portal based on industry driven requirements for people to hone their CNC skills on the shop floor.

Check out our library below!

WBLC Microlearning drives business results with on demand training that immediately improves your employee’s production performance.

What is WBLC Microlearning?

WBLC Microlearning is built upon designing and delivering competency based, industry focused, blended learning for over 600 trainees

WBLC Microlearning is the delivery of specific task based on the job training – modules can be viewed in under 10 minutes.

WBLC Microlearning is delivered on a learners smartphone at their convenience.

WBLC Microlearning ensures the learner’s maximum attention and interest

WBLC Microlearning includes text, graphics, photos, video, and short quizzes

WBLC Microlearning is budget-friendly

Why WBLC Microlearning Works!

WBLC Microlearning works by helping manufacturers assess knowledge, provide effective onboarding, and target specific problem areas for employees.

WBLC Microlearning provides employers with a new and effective way to engage their employees on technical topics that they need to improve their performance.

WBLC Microlearning boosts employee engagement using a variety of learning techniques that result in the learner retaining more knowledge.

Microlearning Modules

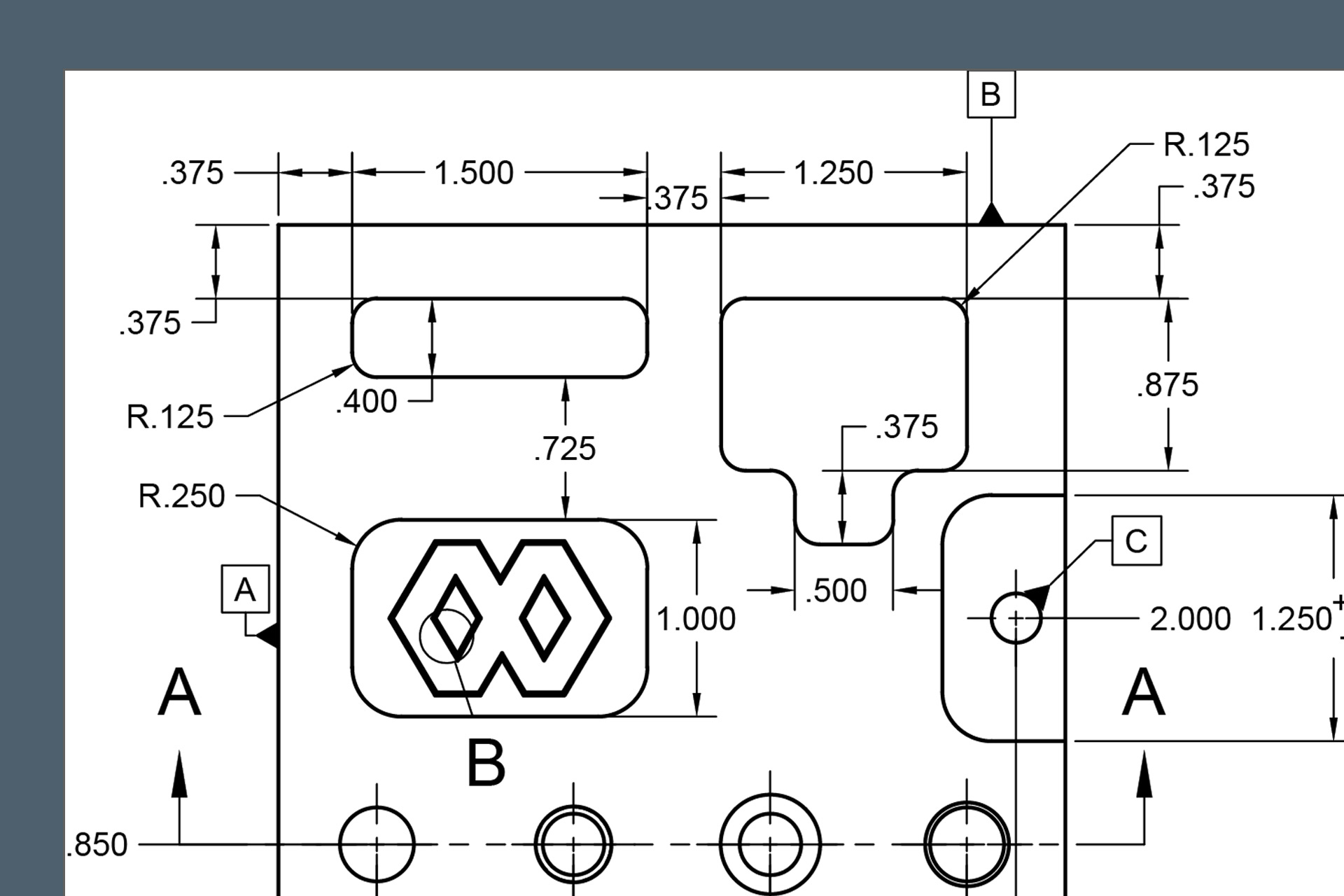

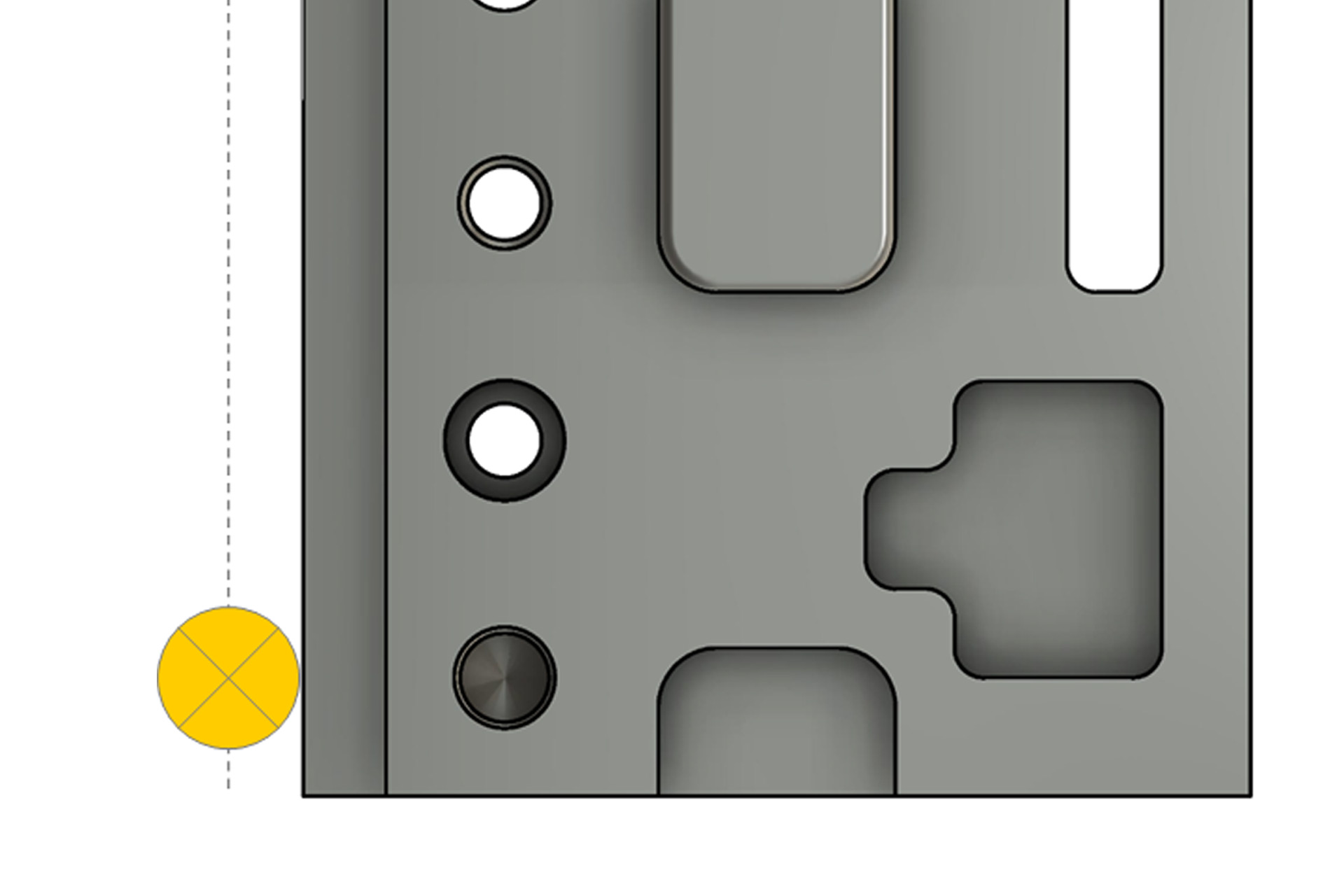

Understanding Blueprints

Blueprints define all the features of a part. In this module, you will learn how to read blueprints accurately to do your job accurately on a CNC machine.

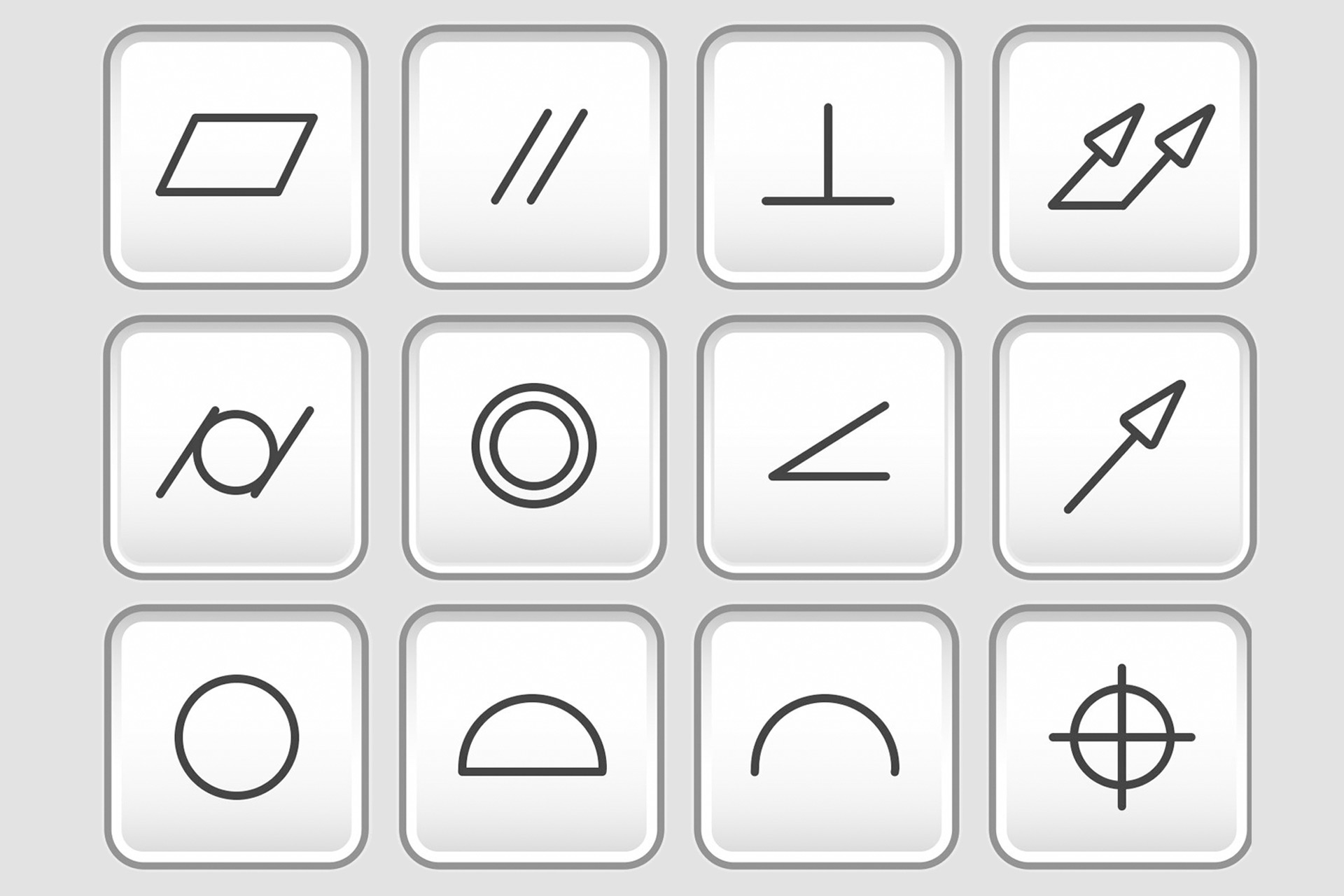

Basics of GD&T

Geometric Dimensioning + Tolerancing is is a system for defining and communicating manufactuing / engineering tolerances. In this module, you will will learn about: Tolerance, GD&T Symbols, and how to read them on blueprints.

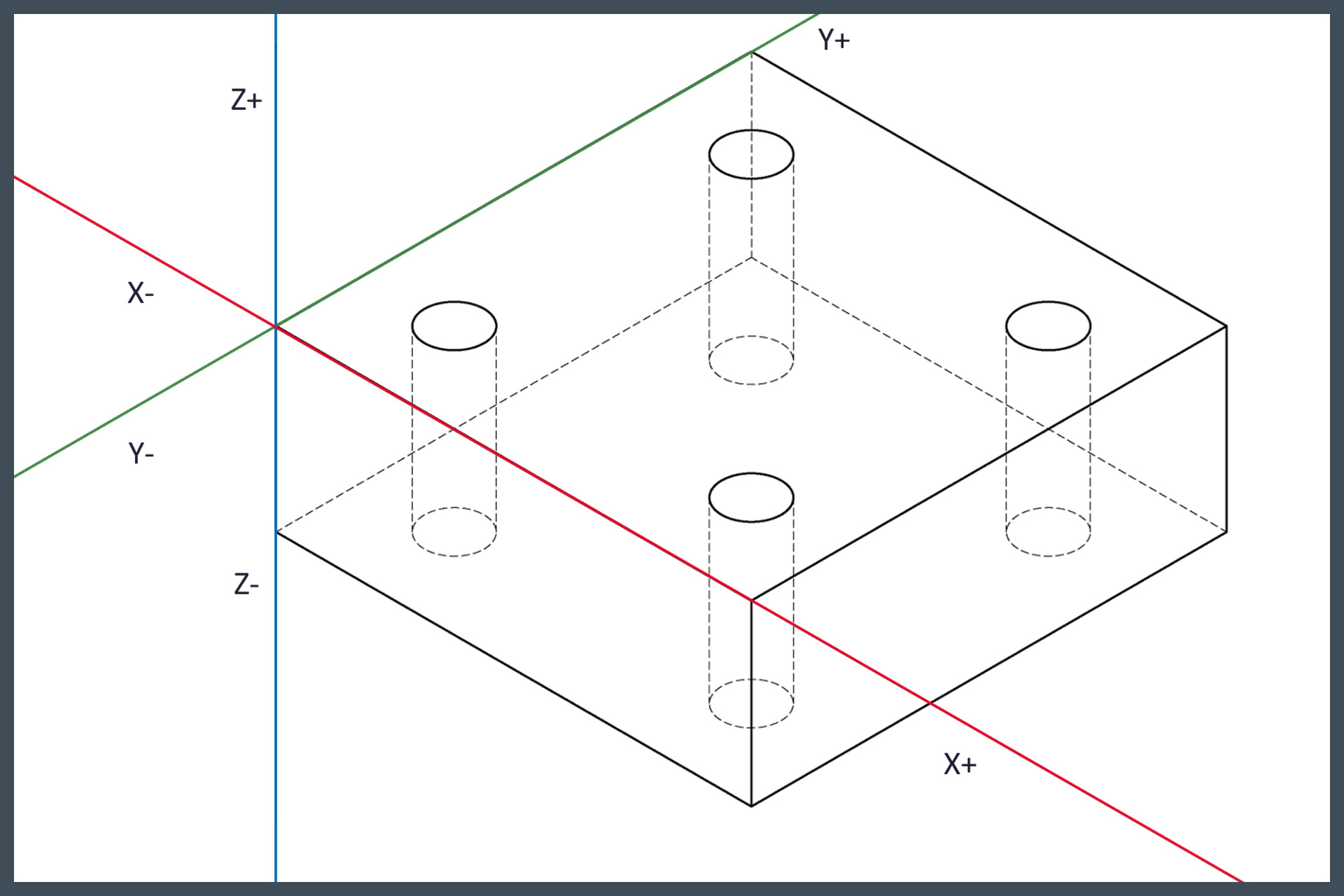

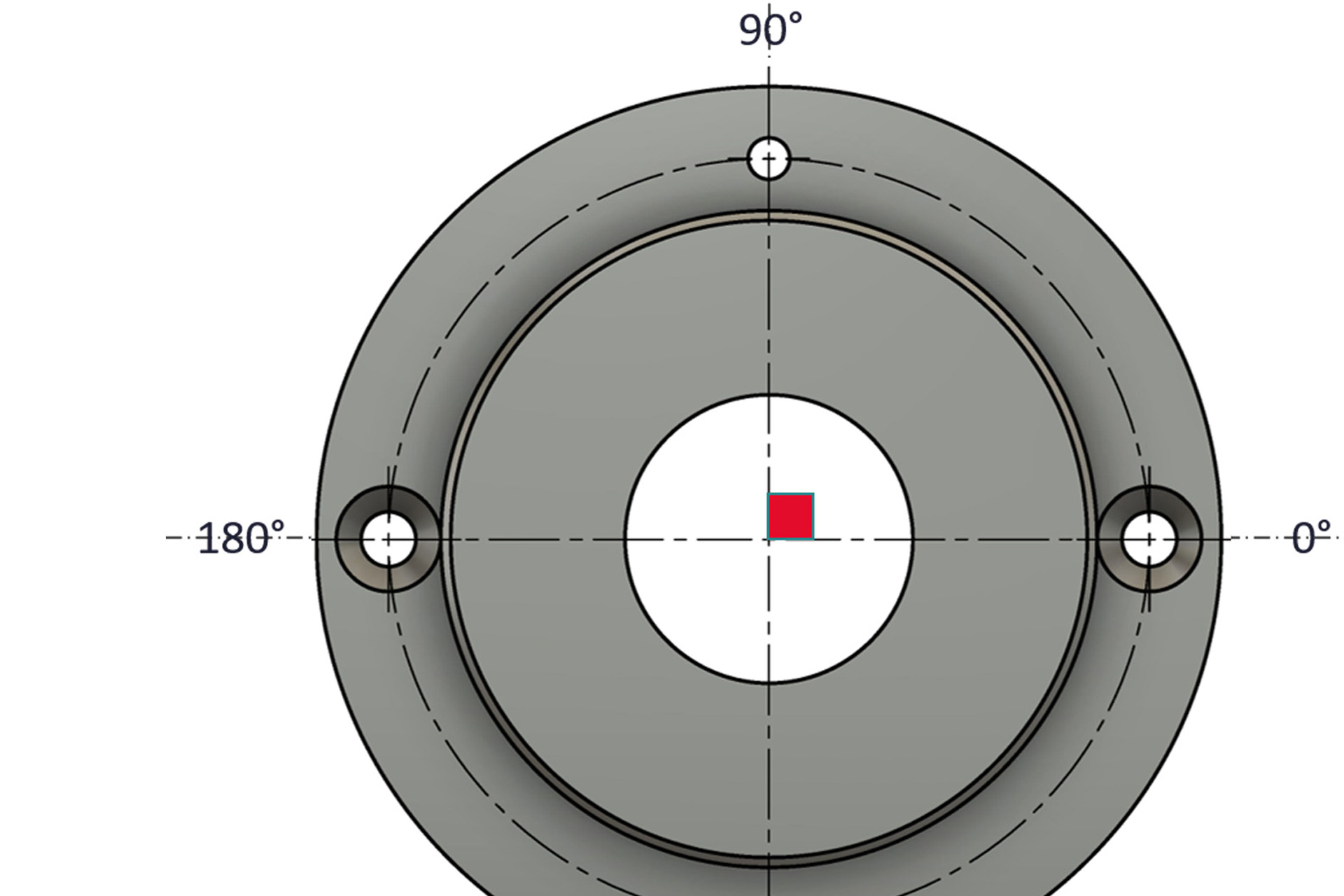

Understanding CNC Co-ordinates

CNC co-ordinates are a set of dimensions measured from a zero ordinate in a drawing or sketch. In this module, you will learn how to understand them in CNC design.

Important CNC Trade Calculations and Formulas

CNC Machinists are always calculating to get the precision that they need for accurate parts. In this module, you will learn important CNC Trade Calculations and how they help you in your job.

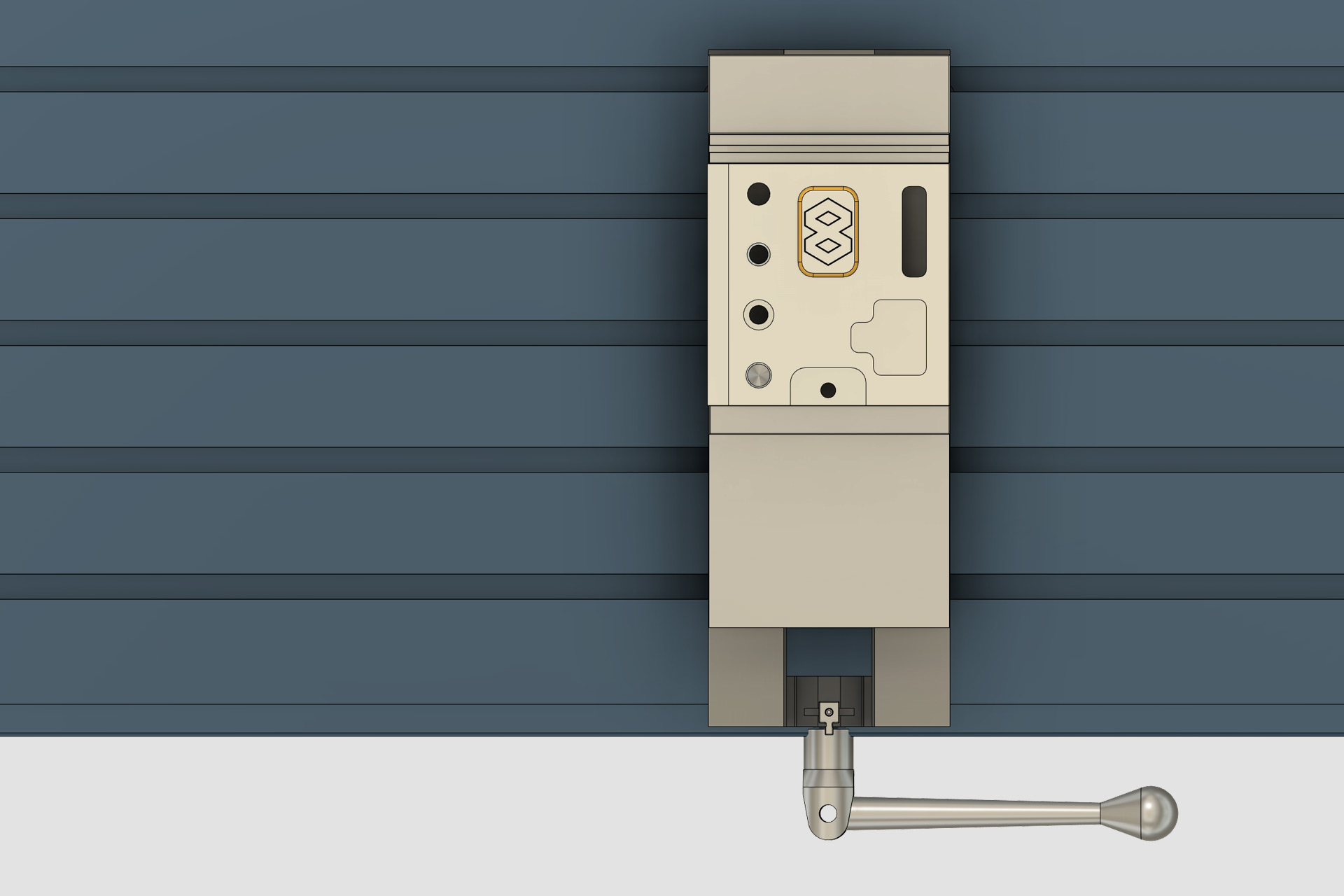

Setting Up A Vise & Workpiece

Setting Up A Vise is an important first step in the machining process. In this module, you will learn the correct way to set up a vise and workpiece on a CNC mill.

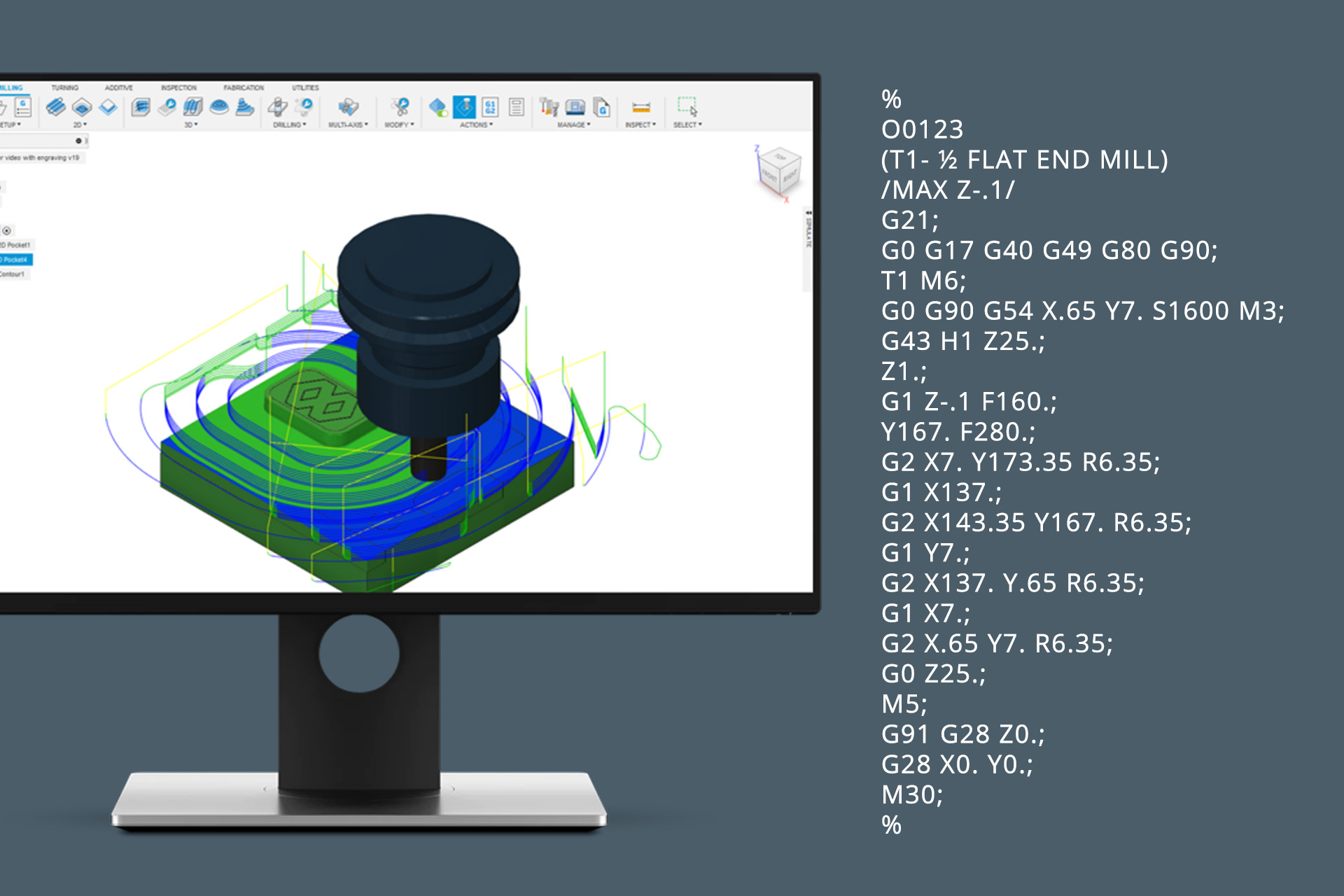

Common M&G Codes

M&G Codes drive CNC machines to cut according to their programs. M codes control functions on a CNC machine, and G codes control the cutting actions. In this module, you will learn the most common M&G codes you need in your job.

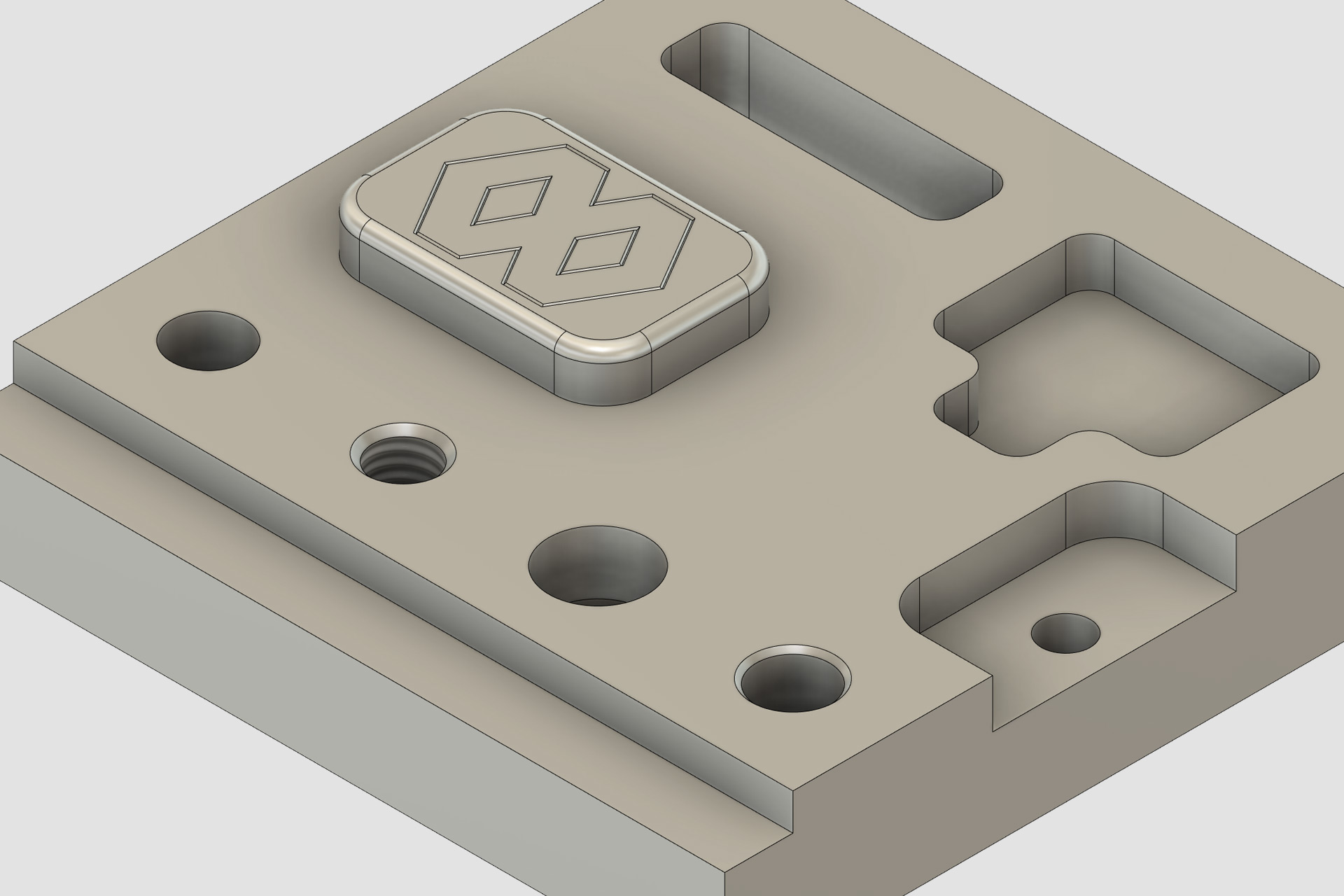

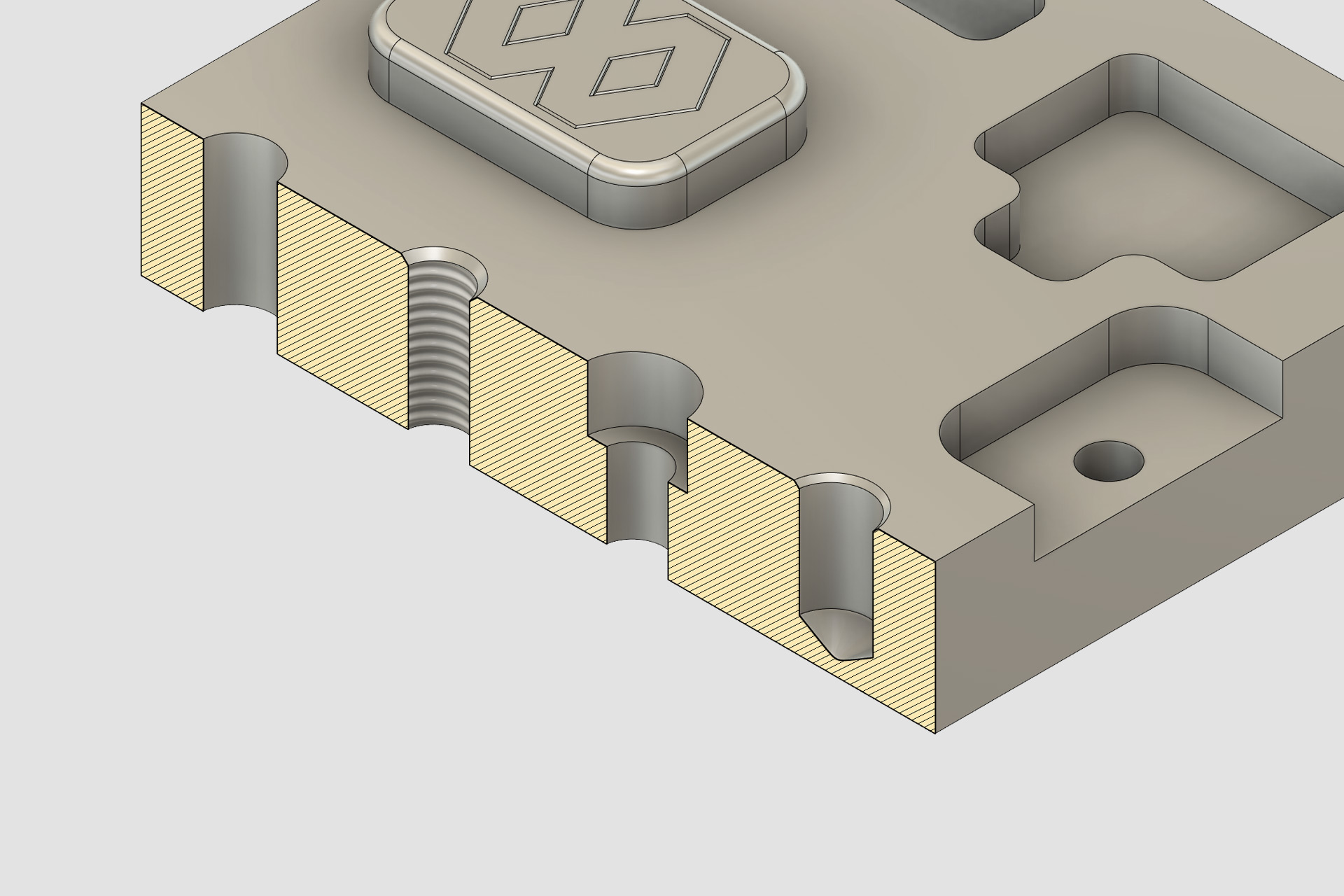

CNC Milling - Roughing and Finishing

In this module, you will learn about different CNC milled part features, tools to create them, and common roughing and finishing operations.

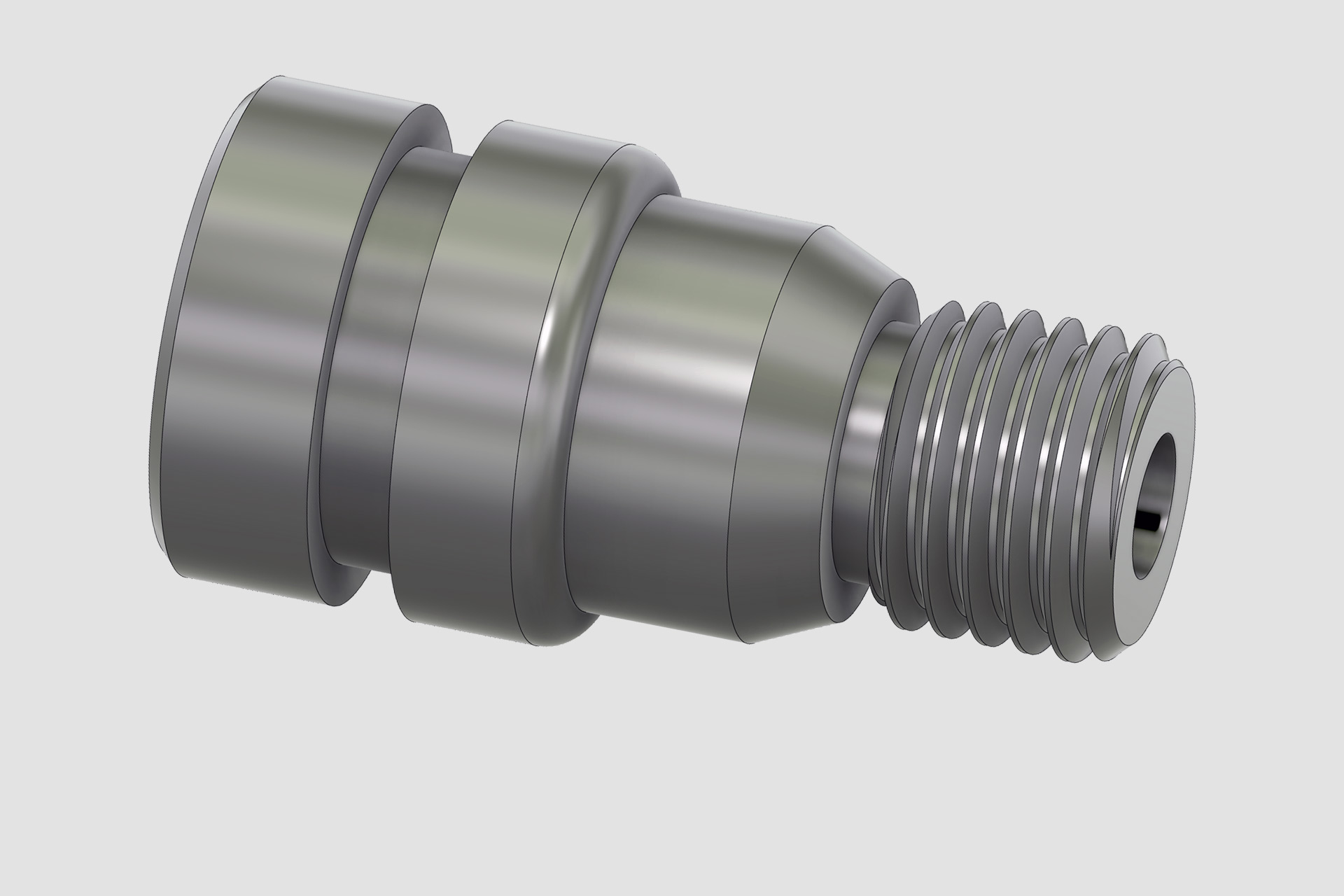

CNC Turning - Roughing and Finishing

In this module, you will learn about different CNC turned part features, tools to create them, and common roughing and finishing operations.

CNC Drilling - Roughing and Finishing

In this module, you will learn about different CNC drilled part features, tools to create them, and common roughing and finishing operations.

Understanding Tool Offsets

Tool offsets provide a way to adjust the toolpath on the machine to compensate for tool size, tool wear, and tool deflection. In this module, you will learn how and when to use them.

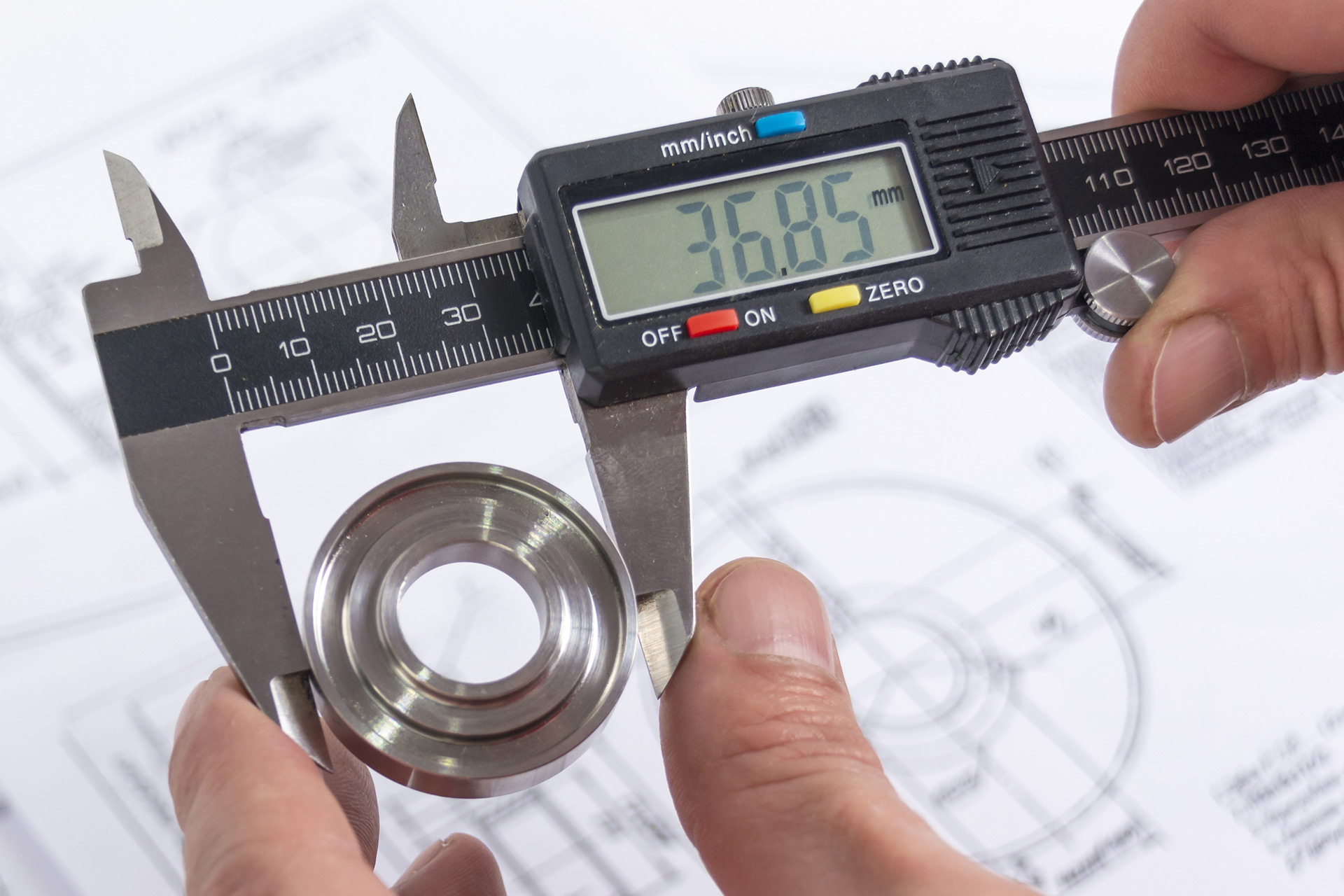

Choosing The Best Precision Measuring Instrument

In this module, you will learn what precision measuring instruments are, how to use them, and how to decide which one works best in different scenarios.