Sep 30, 2020

Harry Garoian is the first graduate to have completed the Mold Maintenance Technician [Level 1] Training Program.

The program helps job seekers learn in-demand skills, get paid on-the-job training, which leads to great stable jobs at Canadian advanced manufacturing companies.

Upon receiving his certificate, Harry said:

“I am delighted to have passed and been certified as a Mold Maintenance Technician [Level 1] by WBLC. As a mid-career worker, it is especially significant to my employer and myself that I successfully completed the program with distinction. I want to thank Peter Drews my Monitor/Coach for his advice and support. Thank you WBLC for the opportunity.”

MP Tool President, AIi Tontonchian said of the program:

“I think the program is good. It was developed specifically to help our industry and the trade in a very practical way. The next step is to build a base and expand it with the other local employers .”

Kim Thiara. President, AceTronic Industrial Controls INC. and Toronto Chapter Chair of CAMM, stated:

Having the opportunity to have had a small part in the creation of this program has been extremely gratifying. As the Toronto Chapter Chair of CAMM, it is our commitment to ensure our industry continues to thrive and flourish well into the future. The Mold Maintenance Technician Program is just one step closer to this goal. We are grateful to WBLC for seeing this come to fruition.

AIi Tontonchian (President, MP Tools President), Harry Garoian, and Blair Munro (Trianer, MP Tools)

WBLC has trained and certified approximately 600 employees for Ontario’s advanced manufacturing sector. Currently WBLC is conducting two programs – Mold Maintenance Technician [level 1] Selection and Learning Program and our CNC Machinist [Level 1] Program. Both are active with their in-takes commencing in October and November.

Detailed information about other programs and services that WBLC is providing can be found at workbasedlearning.ca/programs

Jul 6, 2020

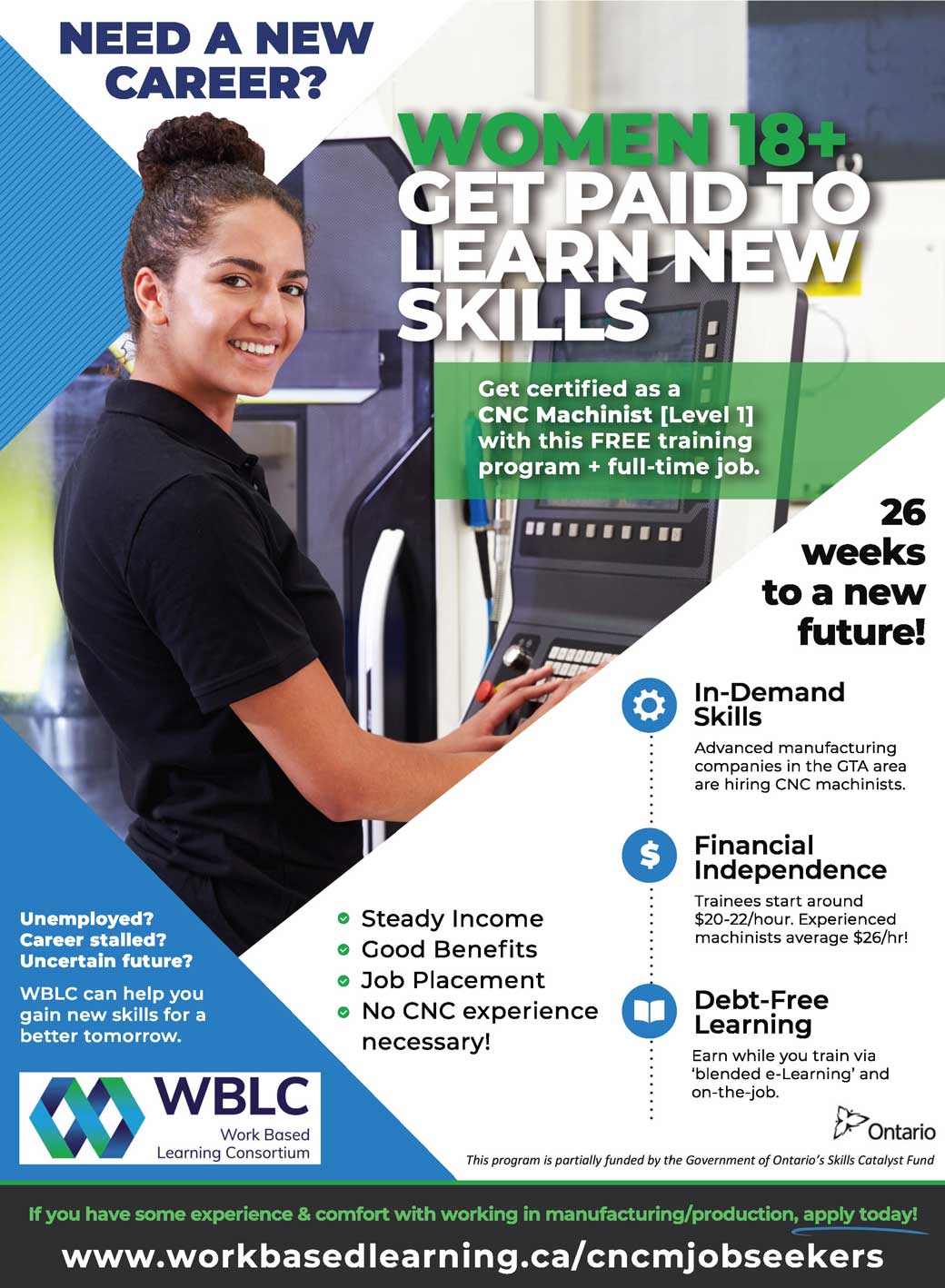

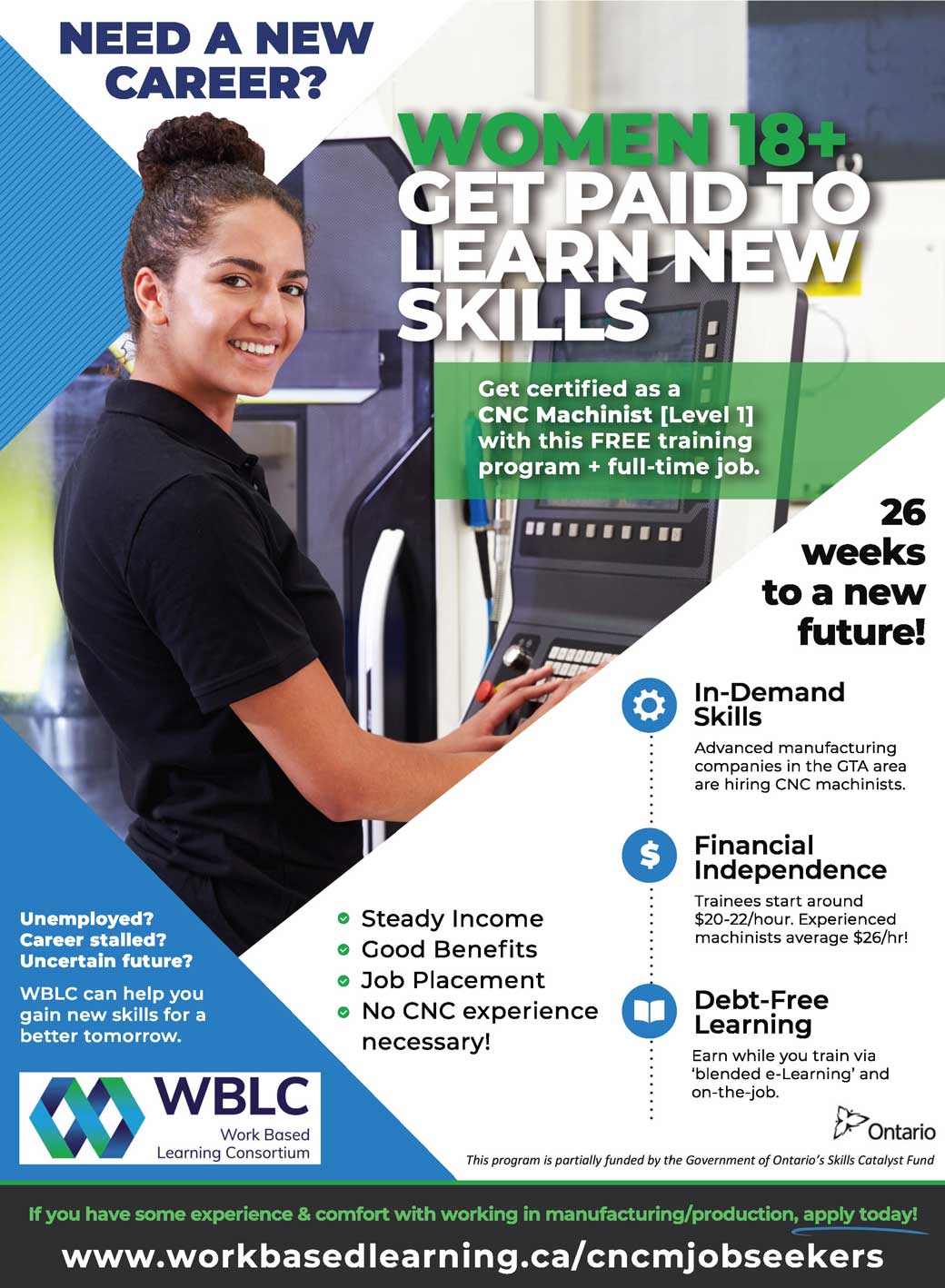

The Work Based Learning Consortium is now recruiting candidates for the CNC Machinist Learning Program – with a start date in early Fall 2020 in the Greater Toronto Area.

CNC Machinist Learning Program

The CNC Machinist learning program is an industry developed program to help talented and hard working people develop CNC Machinist [Level 1] skills while employed in a permanent full time job with an advanced manufacturing company. The Fall 2020 intake has a focus on Women In CNC Machining.

Over 26 weeks, successful candidates will:

- Participate in a one day orientation where they will meet their Coaches and tour a CNC facility.

- Immediately start working full time at an employer where they will be given tasks every day on the job – and get paid!

- Study a comprehensive multimedia e-learning program – developed to teach you the knowledge you require to become competent as a CNC Machinist [Level 1] and complete quizzes, tests, and exams that will measure your knowledge.

- Complete e-learning driven shop floor assignments that reinforce learned concepts.

- Participate in weekly online meetings with a CNC Instructor and the other trainees.

- Attend a 3 day session in the CNC Training Shop where you will get practical hands-on experience on a CNC mill and CNC lathe.

- Get regular guidance and coaching from Shop Floor Trainers.

- Have access to a Coach who will help guide your journey as needed.

- And finally, upon successful completion – get certified as a CNC Machinist [Level 1].

CNC Machinist Learning Program Trainees

We are looking for women 18+ to apply to join our Fall 2020 cohort.

See the flyer below and learn more about the program at www.workbasedlearning.ca/cncmjobseekers to apply today!

Jan 30, 2020

The Work Based Learning Consortium (WBLC) recently launched a comprehensive Mold Maintenance Training Program for mid career workers.

The program is funded by the Government of Canada through a generous grant from the the Future Skill Centre (FSC) to undertake the project “Skilled Jobs and Career Pathways for Mid-Career Workers through Work-Based Learning”.

The program provides a blended learning program for trainees including e-learning, online classroom discussions, in person classes, and on the job shop floor experience.

WBLC programs are unique in many aspects:

- They are always industry-led based on actual requirements from employers. In this case, the Work-Based Learning (WBL) program is designed to find talented and hardworking mid-career job seekers, connect them with companies that are in need of Mold Maintenance Technicians to be hired, trained and certified – quickly, reliably and cost-effectively.

- Our programs are based on industry approved competencies that are then translated into screening, and selection criteria, technical learning objectives and finally certification standards and criteria. WBLC is the only organization in Canada the uses competencies as the basis for all program decision making, thus ensuring reliable and valid outcomes.

- Our programs have very visible and worthwhile outcome – a permanent job for the trainee. For the employer – a new employee with the potential for growth, that is able to be trained and assume complete job duties in very short learning periods. Over the past five years over 90% of our recommended and hired trainees complete their selection and learning program and are certified by WBLC.

WBLC is the preeminent organization supporting business and industry firms in meeting their needs for skilled employees. We design, develop, manage and promote Work-Based Learning programs for entry-level to mid-level skilled jobs that enable unskilled people to get hired, acquire industry-valued skills, achieve industry-recognized certification and pursue rewarding career pathways.

WBLC has trained and certified approximately 600 employees for Ontario’s advanced manufacturing sector. Currently WBLC is conducting two programs – Mold Maintenance Technician [level 1] Selection and Learning Program and our CNC Machinist [Level 1] Program. Both are active with their in-takes commencing in October and November.

Detailed information about other programs and services that WBLC is providing can be found at workbasedlearning.ca/programs

Jun 6, 2019

The Work-Based Learning Consortium (WBLC) has been established as the not-for-profit, federally incorporated organization to design and deliver work-based learning and certification programs. These programs began under the banner of the Ontario Manufacturing Learning Consortium. The focus of the WBLC will be to expand the scale, scope and efficiency of proven, successful, competencies-based programs for many other entry- to mid-level skilled jobs in the manufacturing industry.

Learn more about the vision of the WBLC here >

Meet the WBLC Leadership Team >

Jan 12, 2018

CNC Machinist [Level 1] Selection, Hiring, Learning & Certification Program now available for Companies and Youth in GTA and K-W areas

New funding! New Intakes!

- February 26, 2018 and April 30, 2018 (closed)

- Companies interested in getting capable CNC Machinists – quickly, reliably and at low cost – click here to get details.

- Youth (18-29) interested in getting hired to learn a skilled job and start a good career in advanced manufacturing – click here to get details and apply.

What We Are Looking For

- Youth eligible to work in Ontario between the ages of 18-29

- Youth with the right aptitude, attitude, and personal characteristics

- Youth looking to start a career in manufacturing, specifically machining

The Program

Through both classroom and on the job paid training, successful recruits will be trained to start a career in Ontario’s booming manufacturing industry as CNC Machinists

CNC Machinists

- program, operate, and maintain CNC Machines.

- set up machines that are capable of cutting, bending, forming, and polishing raw metal into finished parts and tools.

- read and interpret blueprints, programs and input data into a computer system

- monitor production, make careful adjustments, and inspect the accuracy of a machine’s operation and resulting parts